-

SingaporeIt is really a pleasure cooperation. You are fast understanding and knowlegeable, also your Check valves worked well. We believe that we will have a great chance to cooperate more.

SingaporeIt is really a pleasure cooperation. You are fast understanding and knowlegeable, also your Check valves worked well. We believe that we will have a great chance to cooperate more. -

ItalyTks for your consisent support for more than 10 years. Your diligence, professional technical support and rich experience in the pipeline projects has biggly help the business between us. Together we will win more and more tenders in the future. Best Regards to you and your team, and finally Come on DEYE Piping team!

ItalyTks for your consisent support for more than 10 years. Your diligence, professional technical support and rich experience in the pipeline projects has biggly help the business between us. Together we will win more and more tenders in the future. Best Regards to you and your team, and finally Come on DEYE Piping team! -

EgyptYou are honnesty and very reliable parnter, tks for your support on the technical data sheets and addtional works to fast the delivery time. Your professional answers are always impressed. also Your products are beautiful. We apprecite all the offorts you have done for the years business.

EgyptYou are honnesty and very reliable parnter, tks for your support on the technical data sheets and addtional works to fast the delivery time. Your professional answers are always impressed. also Your products are beautiful. We apprecite all the offorts you have done for the years business. -

UAEYou are Excellent, especially the quanlity control step by step, We've got all the photos and videos we want. and the documents we received all meet the request. Our boss is very Satisfied and he said he will give you more orders. We like your professional and fast jobs.

UAEYou are Excellent, especially the quanlity control step by step, We've got all the photos and videos we want. and the documents we received all meet the request. Our boss is very Satisfied and he said he will give you more orders. We like your professional and fast jobs. -

PeruThe mould you opened for the valve are good, the new types of butterfly valves is popular. It will biggly increase the business between us. Tks for your suggestions on the flange holes. The valves are in good finishing and well packaged when we received them. Thank you, my friend.

PeruThe mould you opened for the valve are good, the new types of butterfly valves is popular. It will biggly increase the business between us. Tks for your suggestions on the flange holes. The valves are in good finishing and well packaged when we received them. Thank you, my friend. -

KazakhstanThe end user is safisfied with your A234WPB fittings and A105 Flanges, the have finished the welding at present, all works well.Tks for your professional suggestions and the operation manual. We also won the 2nd Phase job, we have sent to you this morning, Pls confirm all the specifications to proceed.

KazakhstanThe end user is safisfied with your A234WPB fittings and A105 Flanges, the have finished the welding at present, all works well.Tks for your professional suggestions and the operation manual. We also won the 2nd Phase job, we have sent to you this morning, Pls confirm all the specifications to proceed.

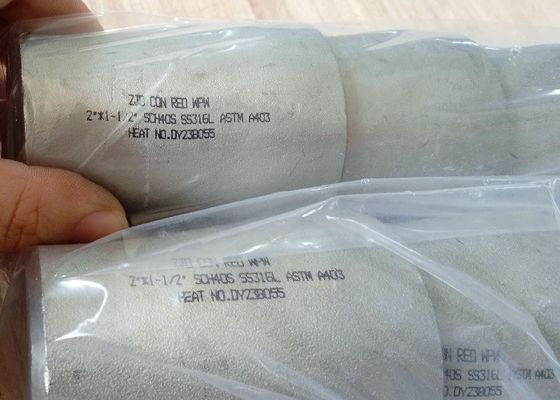

SS316 Stainless Steel Pipe Fittings SS304 SS321 Concentric Reducer Seamless Welded

| Place of Origin | China |

|---|---|

| Brand Name | DEYE |

| Certification | ISO9001: 2015 |

| Model Number | PF-EL-S-02 |

| Document | Product Brochure PDF |

| Minimum Order Quantity | 10pcs |

| Price | USD 2-100 dollars for SS36L Reducers |

| Packaging Details | Ply-Wooden Cases, Pallets , cartons |

| Delivery Time | 10 work days |

| Supply Ability | 25 tons for one month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | SS316/SS316L, SS304/SS304L, SS321, UNS31803, UNS32750 | Connection | Butt Welded BW |

|---|---|---|---|

| Thickness | Sch5s, Sch10s, Sch40s, Sch80s, Sch160s, Xs, Xxs | Surface | Pickling, Polish |

| Highlight | SS316 Stainless Steel Pipe Fittings,SS304 Stainless Steel Pipe Fittings,Seamless stainless steel concentric reducer |

||

SS304 SS321 SS316 Stainless Steel Pipe Fittings Concentric Reducer with Seamless and welded type

Brief Introduction

A buttweld fitting is a weldable pipe fitting that allows for change of direction of flow, to branch off, reduce pipe size or attach auxiliary equipment. Forged Steel buttweld fittings are manufactured in accordance with ANSI / ASME B16.9. Butt weld fittings are available as elbows, tees, caps, reducers and out lets (olets). Buttweld fittings use seamless or welded pipe as the starting material and are formed (through multiple processes) to get the shape of elbows, tees and reducers etc. Just as the pipe is sold from Schedule 10 to Schedule 160, butt weld pipe fittings are sold the same way. Welded butt weld fittings are more common in stainless steel due to cost advantage. Sch 10 fittings are also more common in stainless steel butt weld fittings.

Products Information/Specification:

| Products Name | Butt-Welding Stainless steel seamless and welded Pipe Fitting with standard ANSI B16.9 |

| Types |

Con. Reducers, Ecc. redcuers, LR Elbows, SR Elbow, 180deg Returns, Bends, Reducing Eblow, Straight Tee, Equal Tee, Y Tee, caps, Stub Ends, |

| Size | 1/2"-72" DN15-DN1800 |

| Wall Thickness |

From low thickness to higher thickness SCH5S,SCH10s,SCH20S,SCH30,STD,SCH40S,SCH60,XS,SCH80S,SCH100,SCH120, SCH160S,XXS, DIN, SGP JIS thickness |

| Standard | ASTMA312, ASTM AWP40, ASME, A234WPB A420, ANSI B16.9/B16.28/B16.25 |

| JIS B2311-1997/2312, JIS B2311/B2312, DIN 2605-1/2617/2615, | |

| GB 12459-99,EN Standard etc. | |

| Material | Stainless Steel304, 304L, 304H, 316, 316L, 316H, 310, SS321, SS321H, 347, 347H, 904L |

| Duplex SS 2507, DSS2205, UNS31803 UNS32750 | |

| 1.4301,1.4306, 1.4401, 1.4435, 1.4406, 1.4404, 1.4462, 1.4410, 1.4501 | |

| Carbon Steel A234 WPB, WP5, WP9,WP11, WP22, A420WPL6, A420WPL8 | |

| ST37.0,ST35.8,ST37.2,ST35.4/8,ST42,ST45,ST52,ST52.4 | |

| STP G38,STP G42,STPT42,STB42,STS42,STPT49,STS49 | |

| Surface | Sandblast , acid pickling, Polished |

Features /Characteristics

• Buttweld fittings are available in multiple shapes (elbows, tees, reducers, crosses, caps, stub ends), material grades (carbon, high-yield carbon, low-alloy, stainless, duplex, and nickel alloys)and dimensions (2 to 24 inches in seamless or welded, 26"-72" in welded ).

• Buttweld fittings are pipe fittings used to change the pathway of a pipeline (elbows), reduce/increase the pipe bore size (reducers), branch (tees, cross) or blind a pipeline (butt weld cap)

• The key specifications for buttweld fittings are the ASME B16.9 (carbon and alloy fittings) and the MSS SP 43 (that integrates ASME B16.9 for stainless steel, duplex, and nickel alloy BW fittings).

• butt weld pipe fittings are sold as SCH105S, SCH10S, SCH20S, SCH40S, STD, SCH40, SCH80S, SCH80, SCH160S, XXS

• Welded butt weld fittings are more common in stainless steel due to cost advantage. Sch 10S, SCH40S SS fittings are also more common in stainless steel butt weld fittings.

• Common material for butt weld fittings are A234 WPB, High Yield Carbon Steel, Stainless Steel 304 and 316 and Nickel Alloys.

• Welded pipe fittings in carbon steel and stainless steel are the joining components that make possible the assembly of valves, pipes and equipment onto the piping system.

Technology/ Technical Data Sheets

Thickness List for pipefittings ANSI B16.9

Unit: mm

| Pipe Size DN (in) | Outside Dimeter D | Norminal Wall Thickness | |||||||||||||||

| Sch5s | Sch10S | Sch20 | Sch30 | Sch40s | STD | Sch40 | Sch60 | Sch80s | XS | Sch80 | Sch100 | Schl20 | Schl40 | Sch160 | XXS | ||

| 1/8 | 10. 3 | —— | 1. 24 | —— | —— | 1. 73 | 1. 73 | 1. 73 | —— | 2. 41 | 2. 41 | 2. 41 | —— | —— | —— | —— | —— |

| 1/4 | 13. 7 | — | 1. 65 | — | — | 2. 24 | 2. 24 | 2. 24 | — | 3. 02 | 3. 02 | 3. 02 | — | — | — | — | — |

| 3/8 | 17. 1 | — | 1. 65 | — | — | 2. 31 | 2. 31 | 2. 31 | — | 3. 20 | 3. 20 | 3. 20 | — | — | — | — | — |

| 1/2 | 21. 3 | 1.65 | 2. 11 | —— | —— | 2. 77 | 2. 77 | 2. 77 | —— | 3. 73 | 3. 73 | 3. 73 | —— | —— | —— | 4. 78 | 7. 47 |

| 3/4 | 26. 7 | 1.65 | 2. 11 | —— | —— | 2. 87 | 2. 87 | 2. 87 | —— | 3. 91 | 3. 91 | 3. 91 | —— | —— | —— | 5. 56 | 7. 82 |

| 1 | 33.4 | 1. 65 | 2. 77 | — | — | 3. 38 | 3. 38 | 3. 38 | — | 4. 55 | 4. 55 | 4. 55 | — | — | — | 6. 35 | 9. 09 |

| 1 1/4 | 42. 2 | 1.65 | 2. 77 | — | — | 3. 56 | 3. 56 | 3. 56 | — | 4. 85 | 4. 85 | 4. 85 | — | — | — | 6. 35 | 9. 70 |

| 1 1/2 | 48. 3 | 1.65 | 2. 77 | —— | —— | 3. 68 | 3. 68 | 3. 68 | —— | 5. 08 | 5. 08 | 5. 08 | —— | —— | —— | 7. 14 | 10. 15 |

| 2 | 60. 3 | 1. 65 | 2. 77 | —— | —— | 3. 91 | 3. 91 | 3. 91 | —— | 5. 54 | 5. 54 | 5. 54 | —— | —— | —— | 8. 74 | 11. 07 |

| 2 1/2 | 73. 0 | 2. 11 | 3. 05 | — | — | 5. 16 | 5. 16 | 5. 16 | — | 7. 01 | 7. 01 | 7.01 | — | — | — | 9. 53 | 14. 02 |

| 3 | 88. 9 | 2. 11 | 3. 05 | — | — | 5. 49 | 5. 49 | 5. 49 | — | 7. 62 | 7. 62 | 7. 62 | — | — | — | 11. 13 | 15. 24 |

| 3 1/2 | 101. 6 | 2. 11 | 3. 05 | —— | —— | 5. 74 | 5. 74 | 5. 74 | —— | 8. 08 | 8. 08 | 8. 08 | —— | —— | —— | —— | —— |

| 4 | 114. 3 | 2. 11 | 3. 05 | —— | —— | 6. 02 | 6.02 | 6. 02 | —— | 8. 56 | 8. 56 | 8. 56 | —— | 11. 13 | —— | 13. 49 | 17. 12 |

| 5 | 141. 3 | 2. 77 | 3. 40 | — | — | 6. 55 | 6. 55 | 6. 55 | — | 9. 53 | 9. 53 | 9. 53 | — | 12. 70 | — | 15. 88 | 19. 05 |

| 6 | 168. 3 | 2. 77 | 3. 40 | — | — | 7. 11 | 7. 11 | 7. 11 | — | 10. 97 | 10. 97 | 10. 97 | — | 14. 27 | — | 18. 26 | 21.95 |

| 8 | 219. 1 | 2. 77 | 3. 76 | 6. 35 | 7. 04 | 8. 18 | 8. 18 | 8. 18 | 10. 31 | 12. 70 | 12. 70 | 12. 70 | 15. 09 | 18. 26 | 20. 62 | 23. 01 | 22.23 |

| 10 | 273. 1 | 3. 40 | 4. 19 | 6. 35 | 7. 80 | 9. 27 | 9. 27 | 9.27 | 12. 70 | 12. 70 | 12. 70 | 15. 09 | 18. 26 | 21. 44 | 25. 40 | 28. 58 | 25. 40 |

| 12 | 323.9 | 3. 96 | 4. 57 | 6. 35 | 8. 38 | 9. 53 | 9. 53 | 10. 31 | 14. 27 | 12. 70 | 12. 70 | 17. 48 | 21. 44 | 25. 40 | 28. 58 | 33. 32 | 25. 40 |

| 14 | 355. 6 | 3. 96 | 4. 78 | 7. 92 | 9. 53 | — | 9. 53 | 11. 13 | 15. 09 | — | 12. 70 | 19. 05 | 23. 83 | 27. 79 | 31. 75 | 35. 71 | — |

| 16 | 406. 4 | 4. 19 | 4. 78 | 7. 92 | 9. 53 | —— | 9. 53 | 12. 70 | 16. 66 | —— | 12. 70 | 21. 44 | 26. 19 | 30. 96 | 36. 53 | 40. 49 | —— |

| 18 | 457. 2 | 4. 19 | 4. 78 | 7. 92 | 11. 13 | —— | 9. 53 | 14. 27 | 19. 05 | —— | 12. 70 | 23. 83 | 29. 36 | 34. 96 | 39. 67 | 45. 24 | —— |

| 20 | 508. 0 | 4. 78 | 5. 54 | 9. 53 | 12. 70 | — | 9. 53 | 15. 09 | 20. 62 | — | 12. 70 | 26. 19 | 32. 54 | 38. 10 | 44. 45 | 50. 01 | — |

| 22 | 558. 8 | 4. 78 | 5. 54 | 9. 53 | 12. 70 | — | 9. 53 | — | 22. 23 | — | 12. 70 | 28. 58 | 34. 93 | 41. 28 | 47. 63 | 53. 98 | — |

| 24 | 609. 6 | 5. 54 | 6. 35 | 9. 53 | 14. 27 | —— | 9. 53 | 17. 48 | 24. 61 | —— | 12. 70 | 30. 96 | 38. 89 | 46. 02 | 52. 37 | 59. 54 | —— |

| 26 | 660.4 | —— | —— | 12. 70 | —— | —— | 9. 53 | —— | —— | —— | 12. 70 | —— | —— | —— | —— | —— | —— |

| 28 | 711.2 | — | — | 12. 70 | 15. 88 | — | 9. 53 | — | — | — | 12. 70 | — | — | — | — | — | — |

| 30 | 762. 0 | 6. 35 | 7. 92 | 12. 70 | 15. 88 | — | 9. 53 | — | — | — | 12. 70 | — | — | — | — | — | — |

| 32 | 812. 8 | —— | —— | 12. 70 | 15. 88 | —— | 9. 53 | 17. 48 | —— | —— | 12. 70 | —— | —— | —— | —— | —— | —— |

| 34 | 863. 6 | —— | —— | 12. 70 | 15. 88 | —— | 9. 53 | 17. 48 | —— | —— | 12. 70 | —— | —— | —— | —— | —— | —— |

| 36 | 914. 4 | — | — | 12. 70 | 15. 88 | — | 9. 53 | 17. 48 | — | — | 12. 70 | — | — | — | — | — | — |

| 38 | 965.2 | — | — | — | — | — | 9. 53 | — | — | — | 12. 70 | — | — | — | — | — | — |

| 40 | 1016. 0 | —— | —— | —— | —— | —— | 9. 53 | —— | —— | —— | 12. 70 | —— | —— | —— | —— | —— | —— |

| 42 | 1066. 8 | —— | —— | —— | —— | —— | 9. 53 | —— | —— | —— | 12. 70 | —— | —— | —— | —— | —— | —— |

| 44 | 1117. 6 | — | — | — | — | — | 9. 53 | — | — | — | 12. 70 | — | — | — | — | — | — |

| 46 | 1168.4 | — | — | — | — | — | 9. 53 | — | — | — | 12. 70 | — | — | — | — | — | — |

| 48 | 1219. 2 | — | — | — | — | — | 9. 53 | — | — | — | 12. 70 | — | — | — | — | — | — |

Dimensions of Reducers

![]()

| Nominal Pipe Size (NPS) | Outside Diameter at Bevel | End-to-End, H | Size | Outside Diameter at Bevel | End-to-End, | ||

| Large End | Small End | (NPS) | Large End | Small End | H | ||

| 3/4 x 1/2 | 26.7 | 21.3 | 38 | 5X4 | 141.3 | 114.3 | 127 |

| 3/4 x 3/8 | 26.7 | 17.3 | 38 | 5 x 3’/2 | 141.3 | 101.6 | 127 |

| 1 X 3/4 | 33.4 | 26.7 | 51 | 5X3 | 141.3 | 88.9 | 127 |

| 1 x 1/2 | 33.4 | 21.3 | 51 | 5 x 2’/2 | 141.3 | 73.0 | 127 |

| 1-1/4 X 1 | 42.2 | 33.4 | 51 | 5X2 | 141.3 | 60.3 | 127 |

| 1-1/4 X 3/4 | 42.2 | 26.7 | 51 | 6X5 | 168.3 | 141.3 | 140 |

| 1-1/4 x 1/2 | 42.2 | 21.3 | 51 | 6X4 | 168.3 | 114.3 | 140 |

| 1-1/2 x 1-1/4 | 48.3 | 42.2 | 64 | 6 x 31/, | 168.3 | 101.6 | 140 |

| 1-1/2 X 1 | 48.3 | 33.4 | 64 | 6x3 | 168.3 | 88.9 | 140 |

| 1-1/2X3/4 | 48.3 | 26.7 | 64 | 6 x 27 | 168.3 | 73.0 | 140 |

| 1-1/2X1/2 | 48.3 | 21.3 | 64 | 8x6 | 219.1 | 168.3 | 152 |

| 2 X 1-/2 | 60.3 | 48.3 | 76 | 8X5 | 219.1 | 141.3 | 152 |

| 2 X 1-1/4 | 60.3 | 42.2 | 76 | 8X4 | 219.1 | 114.3 | 152 |

| 2X1 | 60.3 | 33.4 | 76 | 8 x 3-1/2 | 219.1 | 101.6 | 152 |

| 2 X 3/4 | 60.3 | 26.7 | 76 | 10 X 8 | 273.0 | 219.1 | 178 |

| 2-1/2 X 2 | 73.0 | 60.3 | 89 | 10 x 6 | 273.0 | 168.3 | 178 |

| 2-1/2 x 1-1/2 | 73.0 | 48.3 | 89 | 10 x 5 | 273.0 | 141.3 | 178 |

| 2-1/2 X 1-1/4 | 73.0 | 42.2 | 89 | 10 x 4 | 273.0 | 114.3 | 178 |

| 2-1/2 X 1 | 73.0 | 33.4 | 89 | 12 x 10 | 323.8 | 273.0 | 203 |

| 3 X 2-1/2 | 88.9 | 73.0 | 89 | 12 x 8 | 323.8 | 219.1 | 203 |

| 3x2 | 88.9 | 60.3 | 89 | 12 x 6 | 323.8 | 168.3 | 203 |

| 3 x 1-1/2 | 88.9 | 48.3 | 89 | 12 x 5 | 323.8 | 141.3 | 203 |

| 3 x 1-1/4 | 88.9 | 42.2 | 89 | 14 x 12 | 355.6 | 323.8 | 330 |

| 3-1/2 x 3 | 101.6 | 88.9 | 102 | 14 X 10 | 355.6 | 273.0 | 330 |

| 3-1/2x 2-1/2 | 101.6 | 73.0 | 102 | 14 X 8 | 355.6 | 219.1 | 330 |

| 3-1/2 X 2 | 101.6 | 60.3 | 102 | 14 x 6 | 355.6 | 168.3 | 330 |

| 3-1/2 x 1-1/2 | 101.6 | 48.3 | 102 | 16 x 14 | 406.4 | 355.6 | 356 |

| 3-1/2x 1-1/4 | 101.6 | 42.2 | 102 | 16 x 12 | 406.4 | 323.8 | 356 |

| 4 x 3-1/2 | 114.3 | 101.6 | 102 | 16 x 10 | 406.4 | 273.0 | 356 |

| 4X3 | 114.3 | 88.9 | 102 | 16 x 8 | 406.4 | 219.1 | 356 |

| 4 X 2-1/2 | 114.3 | 73.0 | 102 | 18 x 16 | 457 | 406.4 | 381 |

| 4X2 | 114.3 | 60.3 | 102 | 18 x 14 | 457 | 355.6 | 381 |

| 4 x1-1/2 | 114.3 | 48.3 | 102 | 18 x 12 | 457 | 323.8 | 381 |

| 18 x 10 | 457 | 273.0 | 381 | ||||

| Nominal Pipe Size (NPS) | Outside Diameter at Bevel | End-to-End, H | Nominal Pipe Size (NPS) | Outside Diameter at Bevel | End-to-End, H | ||

| Large End | Small End | Large End | Small End | ||||

| 20 X 18 | 508 | 457.0 | 508 | 36 x 34 | 914 | 864 | 610 |

| 20 X 16 | 508 | 406.4 | 508 | 36 x 32 | 914 | 813 | 610 |

| 20 x 14 | 508 | 355.6 | 508 | 36 x 30 | 914 | 762 | 610 |

| 20 x 12 | 508 | 323.8 | 508 | 36 x 26 | 914 | 660 | 610 |

| 36 x 24 | 914 | 610 | 610 | ||||

| 22 X 20 | 559 | 508.0 | 508 | ||||

| 22 X 18 | 559 | 457.0 | 508 | 38 x 36 | 965 | 914 | 610 |

| 22 x 16 | 559 | 406.4 | 508 | 38 x 34 | 965 | 864 | 610 |

| 22 X 14 | 559 | 355.4 | 508 | 38 X 32 | 965 | 813 | 610 |

| 38 x 30 | 965 | 762 | 610 | ||||

| 38 X 28 | 965 | 711 | 610 | ||||

| 24 X 22 | 610 | 559.0 | 508 | 38 x 26 | 965 | 660 | 610 |

| 24 X 20 | 610 | 508.0 | 508 | ||||

| 24 x 18 | 610 | 457.0 | 508 | 40 x 38 | 1 016 | 965 | 610 |

| 24 X 16 | 610 | 406.4 | 508 | 40 x 36 | 1 016 | 914 | 610 |

| 40 X 34 | 1 016 | 864 | 610 | ||||

| 26 x 24 | 660 | 610.0 | 610 | 40 X 32 | 1 016 | 813 | 610 |

| 26 X 22 | 660 | 559.0 | 610 | 40 x 30 | 1 016 | 762 | 610 |

| 26 X 20 | 660 | 508.0 | 610 | ||||

| 26 X 18 | 660 | 457.0 | 610 | 42 X 40 | 1 067 | 1 016 | 610 |

| 42 X 38 | 1 067 | 965 | 610 | ||||

| 28 X 26 | 711 | 660.0 | 610 | 42 x 36 | 1 067 | 914 | 610 |

| 28 X 24 | 711 | 610.0 | 610 | 42 X 34 | 1 067 | 864 | 610 |

| 28 x 20 | 711 | 508.0 | 610 | 42 X 32 | 1 067 | 813 | 610 |

| 28 X 18 | 711 | 457.0 | 610 | 42 X 30 | 1 067 | 762 | 610 |

| 30 X 28 | 762 | 711.0 | 610 | 44 X 42 | 1 118 | 1 067 | 610 |

| 30 X 26 | 762 | 660.0 | 610 | 44 X 40 | 1 118 | 1 016 | 610 |

| 30 X 24 | 762 | 610.0 | 610 | 44 X 38 | 1 118 | 965 | 610 |

| 30 X 20 | 762 | 508.0 | 610 | 44 X 36 | 1 118 | 914 | 610 |

| 32 X 30 | 813 | 762.0 | 610 | 46 X 44 | 1 168 | 1 118 | 711 |

| 32 X 28 | 813 | 711.0 | 610 | 46 X 42 | 1 168 | 1 067 | 711 |

| 32 x 26 | 813 | 660.0 | 610 | 46 x 40 | 1 168 | 1 016 | 711 |

| 32 x 24 | 813 | 610.0 | 610 | 46 x 38 | 1 168 | 965 | 711 |

| 34 x 32 | 864 | 813.0 | 610 | 48 x 46 | 1 219 | 1 168 | 711 |

| 34 X 30 | 864 | 762.0 | 610 | 48 X 44 | 1 219 | 1 118 | 711 |

| 34 x 26 | 864 | 660.0 | 610 | 48 x 42 | 1 219 | 1 067 | 711 |

| 34 x 24 | 864 | 610.0 | 610 | 48 x 40 | 1 219 | 1 016 | 711 |

Stainless steel is the abbreviation for stainless and acid resistant steel. Steel that is resistant to weak corrosive media such as air, steam, water, or has rust resistance is called stainless steel; And the steel grade that is resistant to chemical corrosion media (such as acid, alkali, salt, etc.) corrosion is called acid resistant steel.For the Stainless Steel pipefittings, the most common used material is SS304/304L, SS316/316L, DUPLEX SAF2507, SAF2205

Production Process

![]()

Application/Usage

Low and middle pressure fluid pipeline,boiler, petroleum and natural gas industry, drilling,chemical industry, electric industry,shipbuilding,fertilizer equipment and pipeline, structure,petrochemical,pharmaceutical industry,etc.

FAQ/ Customer Question and Answers

Q:Customer asked for butt weld fittings in A105:

A: Most common carbon steel buttweld fitting material is A234WPB. It is equivalent to A105 flanges, however there is no such thing as an A105 or A106 butt weld fitting. A106 Gr.B is for pipe grade. The A234WPB fittings are made from A106GR.B pipes. A105 is a material from Bar forged to be High pressure Fittings or Flange

Q: Customer requests “Normalized” butt weld fittings:

A: This is also a misconception since flanges are available in A105 and A105 N, where N stands for normalized.

However, there is no such thing as A234WPBN. Manufactures normalize their butt weld fittings was considered that normalized heat treating process was done, Espeically for the elbows and Tees

Customer needing “normalized” butt weld fittings should request WPL6 fittings which are high yield and are normalized as a standard procedure.

Q: Customer forgets to mention pipe schedule:

A: Buttweld fittings are sold as per pipe size but pipe schedule must be specified to match the ID of the fitting to the ID of the pipe. If no schedule is mentioned, we will assume a standard wall is requested.

Q: Customer forgets to mention welded or seamless butt weld fitting:

A: Butt weld fittings are available in both welded and seamless configuration. A seamless butt weld carbon steel or stainless steel fitting is made of seamless pipe and is generally more expensive.

Seamless pipe fittings are NOT common in sizes bigger than 12”. Welded pipe fittings are made of ERW welded carbon steel or stainless steel pipe. They are available in sizes ½” to 72” and are more affordable than seamless fittings.

Q: What does Short Radius (SR) or Long Radius (LR) means?

A: You will often hear SR45 elbow or LR45 elbow. The 45 or 90 refers to the angle of the bend for buttweld fitting to change the direction of flow.

A long radius elbow (LR 90 Elbow or LR 45 elbow) will have a pipe bend that will be 1.5 times the size of the pipe. So, a 6 inch LR 90 has bending radius that is 1.5 x nominal pipe size.

A short radius elbow (SR45 or SR90) has a pipe bend that is equal to the size of the fitting, so a 6” SR 45 has a bending radius that is 6” nominal pipe size.

Q: What is a 3R or 3D elbow pipe fitting?

A: First, the terms 3R or 3D are used synonymously. A 3R butt weld elbow has a bending radius that is 3 times the nominal pipe size. A 3R elbow is equal to 3D Elbows

Our Service

1. Technical support

2. Raw Material Quality control.

3. Inspection during the production time.

4. Final Test includes Surface, Dimension, PT Test, RT test, ultrasonic Test

5. Test Report each shipment

4. Flexible Delivery terms. EXW FOB CIF CFR DDP DDU

5. Flexible payment Ways: LC. TT. DP

6. Customized Package includes Logo. Cases Dimension.

7. 18 months quality Guarantee time.

9. Free replacement by air if any error founded

10. 24 hours to Feedback your questions