-

SingaporeIt is really a pleasure cooperation. You are fast understanding and knowlegeable, also your Check valves worked well. We believe that we will have a great chance to cooperate more.

SingaporeIt is really a pleasure cooperation. You are fast understanding and knowlegeable, also your Check valves worked well. We believe that we will have a great chance to cooperate more. -

ItalyTks for your consisent support for more than 10 years. Your diligence, professional technical support and rich experience in the pipeline projects has biggly help the business between us. Together we will win more and more tenders in the future. Best Regards to you and your team, and finally Come on DEYE Piping team!

ItalyTks for your consisent support for more than 10 years. Your diligence, professional technical support and rich experience in the pipeline projects has biggly help the business between us. Together we will win more and more tenders in the future. Best Regards to you and your team, and finally Come on DEYE Piping team! -

EgyptYou are honnesty and very reliable parnter, tks for your support on the technical data sheets and addtional works to fast the delivery time. Your professional answers are always impressed. also Your products are beautiful. We apprecite all the offorts you have done for the years business.

EgyptYou are honnesty and very reliable parnter, tks for your support on the technical data sheets and addtional works to fast the delivery time. Your professional answers are always impressed. also Your products are beautiful. We apprecite all the offorts you have done for the years business. -

UAEYou are Excellent, especially the quanlity control step by step, We've got all the photos and videos we want. and the documents we received all meet the request. Our boss is very Satisfied and he said he will give you more orders. We like your professional and fast jobs.

UAEYou are Excellent, especially the quanlity control step by step, We've got all the photos and videos we want. and the documents we received all meet the request. Our boss is very Satisfied and he said he will give you more orders. We like your professional and fast jobs. -

PeruThe mould you opened for the valve are good, the new types of butterfly valves is popular. It will biggly increase the business between us. Tks for your suggestions on the flange holes. The valves are in good finishing and well packaged when we received them. Thank you, my friend.

PeruThe mould you opened for the valve are good, the new types of butterfly valves is popular. It will biggly increase the business between us. Tks for your suggestions on the flange holes. The valves are in good finishing and well packaged when we received them. Thank you, my friend. -

KazakhstanThe end user is safisfied with your A234WPB fittings and A105 Flanges, the have finished the welding at present, all works well.Tks for your professional suggestions and the operation manual. We also won the 2nd Phase job, we have sent to you this morning, Pls confirm all the specifications to proceed.

KazakhstanThe end user is safisfied with your A234WPB fittings and A105 Flanges, the have finished the welding at present, all works well.Tks for your professional suggestions and the operation manual. We also won the 2nd Phase job, we have sent to you this morning, Pls confirm all the specifications to proceed.

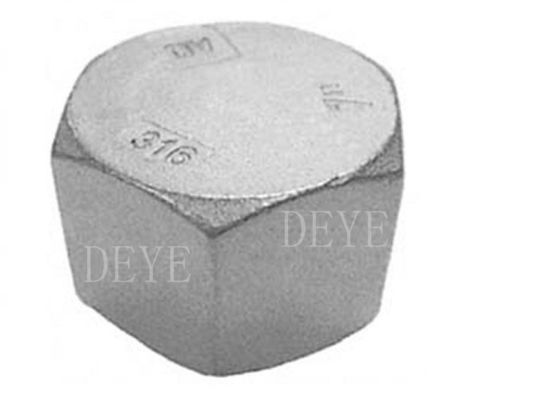

SS201 SS304 SS316 150# Stainless Steel screw plugs caps with NPT BSPT

| Place of Origin | China |

|---|---|

| Brand Name | DEYE |

| Certification | ISO9001:2015 PED |

| Model Number | STH-TH-24 |

| Document | Product Brochure PDF |

| Minimum Order Quantity | 10pcs |

| Price | USD0.5-USD50 for each pc |

| Packaging Details | Cartons+Ply-wooden cases, Pallets |

| Delivery Time | 7 days for stock items |

| Payment Terms | T/T, L/C, D/P |

| Supply Ability | 1000000PCS one month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Thread | DIN 2999, ISO 7/1, ISO 228, NPT, BSPT, BSP | Casting | Investment Casting |

|---|---|---|---|

| Material | 304/304L, 316/316L | Size | 1/4"-4" |

| Highlight | BSPT stainless steel npt pipe fittings,50PSI stainless steel npt pipe fittings,SS201 ss threaded fittings |

||

SS201 SS304 SS316 50PSI NPT BSPT STAINLESS STEEL SCREWED THREADED PIPE FITTINGS

Class 150 hex head caps are also called hex. Plugs, they are stainless steel 304 or 316 cast pipe fitting with female National Pipe Taper (NPT) threads for stopping flow. the stainless steel castings confom to ASTM A351 ACI Grade CF8 (304) & ACI Grade CF8M (316), These hex head caps have NPT threads with standard of ASME B1.20.1 and BSPP BSPT DIN2999, The hex head plugs/caps threaded for creating tighter seals than straight threads.

The Class 150 hex head plugs are suitable for medium of air, water, oil, natural gas, steam , Maximum Pressure: 300 psi @ 72 F;150 psi @ 366 F for steam

Product Information/Product Description/Basis Information/Specification

| Descriptio | SS201 SS304 SS316 150# Stainless Steel screw plugs caps with NPT BSPT |

| Product name | threaded NPT BSPT 150PSI Elbows, Reducers, Coupling, Plug, Bushing, Union, Tee, cross, caps Stainless Steel Screwed Pipe Fittings Threaded Pipe Fittings Union, Hex Nipple, bushing, reducer socket, 45 90 degree elbow, Square Head plug, coupling, Y pipe joints tee |

| Size | 1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2" 3" 4" 5" 6" 8" |

| Gasket | NBR, FKM |

| Thread | BSPT,BSPP, NPT,PS , DIN |

| Material | stainless steel201,202, stainless steel304, stainless steel 316 |

| Casting Method | Investment precision casting, CNC machine |

| Application | Oil, Water, Industrial, Chemical |

| Test pressure | Usually 150PSI |

| Package | pcs/polybag, polybag/carton, cartons/pallet or according to your requirement |

| Advantages | 1.OEM and Customized service can be provided |

| 2. With experience,quality guaranteed | |

| 3. Approved by ISO9001:2015 | |

| 4. With independent open mold capacity, OEM supposed |

Technology/ Technical Data Sheets

| 90° Elbow | 90° Street Elbow | 45° Elbow | |||

| Tee | Cross | Hex. Nipple | |||

| Hex. Plug | Square Plug | Hex. Cap | |||

| Round Cap | Coupling (Socket) | Half Coupling | |||

| SIZE | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 | L10 | L11 | L12 |

| 1/8” | 16 | 18 | 16 | 17 | 25 | 22 | 18 | 17 | 13 | - | - | - |

| 1/4” | 19 | 19 | 19 | 20 | 30 | 30 | 18 | 21 | 15 | 15 | 25 | 11 |

| 3/8” | 24 | 20 | 25 | 24 | 34 | 31 | 19 | 23 | 17 | 17 | 26 | 12 |

| 1/2” | 25.5 | 20 | 28 | 26 | 37 | 35 | 22 | 24 | 19 | 17.5 | 32 | 15 |

| 3/4” | 29.5 | 23 | 32 | 30 | 43 | 39 | 24 | 25 | 18 | 20.5 | 33 | 17 |

| 1” | 36 | 26 | 39 | 36 | 51 | 45 | 27 | 27 | 20.5 | 23.5 | 38 | 19 |

| 1-1/4” | 43.5 | 30 | 45 | 44 | 59 | 48 | 26 | 34.5 | 22 | 25.5 | 44 | 22 |

| 1-1/2” | 46.5 | 33 | 49 | 47 | 64 | 50 | 29.5 | 35.5 | 23 | 26.5 | 44 | 23 |

| 2” | 55.5 | 38 | 57 | 54 | 74 | 57 | 32 | 36 | 25.5 | 28 | 50 | 25 |

| 2-1/2” | 66 | 45 | 69 | 66 | 90 | 64 | 36.5 | 43 | 28.5 | 31 | 58 | 29 |

| 3” | 74 | 52 | - | 74 | 99 | 70 | 37.5 | 46.5 | 30.5 | 33 | 66 | 33 |

| 4” | 90 | 64 | - | 90 | 115 | 79 | 42 | 52 | 38.5 | 37 | 72 | 36 |

Production Process

![]()

Common used Material Grade

SS316 Chemical Composition

ASTM A351 CF8M, SS316 Chemical Composition in %

| ASTM A351 CF8M, SS316 Chemical Composition in % | ||||||||

| C | Mn | P | S | Si | Ni | Cr | Mo | |

| Min. | 9.0 | 18.0 | 2.00 | |||||

| Max. | 0.080 | 1.500 | 0.040 | 0.040 | 1.500 | 12.0 | 21.0 | 3.00 |

SS316 Mechanical Properties of the Fittings at room temperature

| SS316/SS316L | Tensile Strength Rm (N/mm2) | Upper Yield Point ReH (N/mm2) min. | Elongation at rupture A5 (%) min. |

Hardness Test (HRB) |

| Min. | 485 | 205 | 30 | |

| Max. | 80 |

SS304 Chemical Composition

| ASTM A351 CF8, SS304 Chemical Composition in % | ||||||||

| C | Mn | P | S | Si | Ni | Cr | Mo | |

| Min. | 8.0 | 18.0 | ||||||

| Max. | 0.080 | 1.500 | 0.040 | 0.040 | 2.000 | 11.0 | 21.0 | 0.50 |

SS304 Mechanical Properties of the Fittings at room temperature

| SS304/SS304L | Tensile Strength Rm (N/mm2) | Upper Yield Point ReH (N/mm2) min. | Elongation at rupture A5 (%) min. |

Hardness Test (HRB) |

| Min. | 485 | 205 | 35 | |

| Max |

Application/ Usage:

Threaded pipe fittings are commonly used in Water gas pipes, small diameter water pipes, compressed air pipes and low-pressure steam pipes.