-

SingaporeIt is really a pleasure cooperation. You are fast understanding and knowlegeable, also your Check valves worked well. We believe that we will have a great chance to cooperate more.

SingaporeIt is really a pleasure cooperation. You are fast understanding and knowlegeable, also your Check valves worked well. We believe that we will have a great chance to cooperate more. -

ItalyTks for your consisent support for more than 10 years. Your diligence, professional technical support and rich experience in the pipeline projects has biggly help the business between us. Together we will win more and more tenders in the future. Best Regards to you and your team, and finally Come on DEYE Piping team!

ItalyTks for your consisent support for more than 10 years. Your diligence, professional technical support and rich experience in the pipeline projects has biggly help the business between us. Together we will win more and more tenders in the future. Best Regards to you and your team, and finally Come on DEYE Piping team! -

EgyptYou are honnesty and very reliable parnter, tks for your support on the technical data sheets and addtional works to fast the delivery time. Your professional answers are always impressed. also Your products are beautiful. We apprecite all the offorts you have done for the years business.

EgyptYou are honnesty and very reliable parnter, tks for your support on the technical data sheets and addtional works to fast the delivery time. Your professional answers are always impressed. also Your products are beautiful. We apprecite all the offorts you have done for the years business. -

UAEYou are Excellent, especially the quanlity control step by step, We've got all the photos and videos we want. and the documents we received all meet the request. Our boss is very Satisfied and he said he will give you more orders. We like your professional and fast jobs.

UAEYou are Excellent, especially the quanlity control step by step, We've got all the photos and videos we want. and the documents we received all meet the request. Our boss is very Satisfied and he said he will give you more orders. We like your professional and fast jobs. -

PeruThe mould you opened for the valve are good, the new types of butterfly valves is popular. It will biggly increase the business between us. Tks for your suggestions on the flange holes. The valves are in good finishing and well packaged when we received them. Thank you, my friend.

PeruThe mould you opened for the valve are good, the new types of butterfly valves is popular. It will biggly increase the business between us. Tks for your suggestions on the flange holes. The valves are in good finishing and well packaged when we received them. Thank you, my friend. -

KazakhstanThe end user is safisfied with your A234WPB fittings and A105 Flanges, the have finished the welding at present, all works well.Tks for your professional suggestions and the operation manual. We also won the 2nd Phase job, we have sent to you this morning, Pls confirm all the specifications to proceed.

KazakhstanThe end user is safisfied with your A234WPB fittings and A105 Flanges, the have finished the welding at present, all works well.Tks for your professional suggestions and the operation manual. We also won the 2nd Phase job, we have sent to you this morning, Pls confirm all the specifications to proceed.

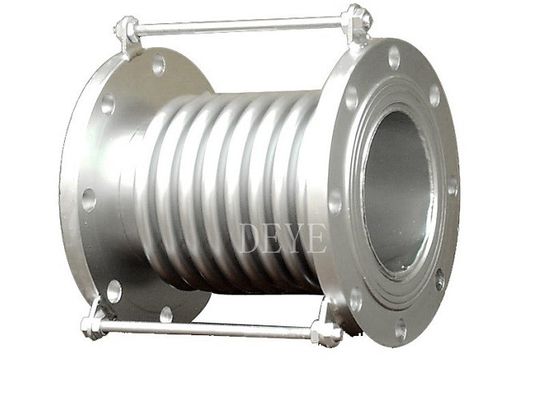

SS Metal Bellows Expansion Joints With CL150 PN16 PN25

| Place of Origin | CHINA |

|---|---|

| Brand Name | DEYE |

| Certification | ISO9001:2015 PED |

| Model Number | DY-RJ-U12 |

| Document | Product Brochure PDF |

| Minimum Order Quantity | 10PCS |

| Price | USD2-USD25 each |

| Packaging Details | carton box+ ply wooden cases or carton+ Pallets |

| Delivery Time | 20 days for usual order, 7 days for stocked items |

| Payment Terms | T/T, L/C, D/P |

| Supply Ability | 1000pcs one month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Types | Single Sphere Type, Twin Sphere Type, Double Sphere Type, Double Ball Type, Union Fittings Type | Rubber Material | EPDM, NBR, BUNA, Neoprene, VITON, PTFE, Hypalon |

|---|---|---|---|

| Flange Type | HDG, Electric. Galvanized, Zinc Coated, Stainless Steel | Rating | PN10 PN16 PN25 CL150LBS 150# |

| Size | 2" (DN50MM)-144"(DN3600MM) | ||

| Highlight | Metal bellows expansion joints,SS bellows expansion joints,PN25 bellow joint expansion |

||

SS METAL BELLOWS EXPANSION JOINT WITH CL150 PN16 PN25

Metal expansion joints are compensating elements for thermal expansion and relative motion in pipelines, containers, and machines.

Depending on the application, they are composed of one or more metal corrugated pipes, connectors at both ends, and pull rods.

They differ based on three basic types of motion: axial, angular, and lateral expansion joints. Expansion joints are used in various fields

such as energy production, papermaking industry, chemical industry, water treatment, oil and natural gas. Expansion joints can be used

regardless of thermal motion or vibration in the pipeline.

Size Range:

1”-48”

Project Material Grade:

Carbon Steel: ST37, Q235, A105

Austenitic Stainless Steels: 304 SS, 321 SS, 304L SS, 347 SS, 310 SS, 316 SS, 316L SS, 904L

Nickel Alloys: Inconel 600, Inconel 601, Inconel 625, Incoloy 800, Incoloy 800H, Incoloy 825, Monel 400,

Technical Drawings of meal expansion joint/ Metallic Expansion Joint

![]()

Type 01 Dimension

| Size | Ripple | Working Pressure(bar) | Effective | Max. | Supplied Length(mm) | ||||||||

| 10 | 16 | 25 | 10 | 16 | 25 | area | OD | ||||||

| DN | qty | Axial Compensation(mm) | Force for Compress(N/mm) | (cm2) | (mm) | Flanged End | Welded End | ||||||

| 32 | 8 | 20 | 18 | 15 | 26 | 63 | 98 | 16 | 225 | 160 | 250 | 264 | 280 |

| 40 | 8 | 20 | 18 | 15 | 44 | 89 | 106 | 23 | 244 | 164 | 259 | 269 | 289 |

| 50 | 8 | 20 | 18 | 15 | 70 | 70 | 138 | 37 | 259 | 172 | 276 | 282 | 306 |

| 65 | 8 | 26 | 22 | 19 | 44 | 55 | 68 | 55 | 270 | 215 | 294 | 300 | 322 |

| 80 | 8 | 34 | 28 | 25 | 33 | 41 | 54 | 81 | 284 | 240 | 338 | 344 | 366 |

| 100 | 6 | 40 | 35 | 29 | 75 | 93 | 117 | 121 | 304 | 235 | 317 | 323 | 345 |

| 125 | 5 | 38 | 34 | 29 | 59 | 74 | 92 | 180 | 334 | 282 | 314 | 316 | 342 |

| 150 | 5 | 40 | 34 | 29 | 62 | 78 | 97 | 257 | 364 | 282 | 339 | 338 | 367 |

| 200 | 4 | 42 | 38 | 34 | 68 | 78 | 111 | 479 | 442 | 280 | 348 | 348 | 372 |

| 250 | 4 | 59 | 52 | 47 | 42 | 45 | 55 | 769 | 507 | 315 | 379 | 415 | 379 |

| 300 | 4 | 59 | 52 | 47 | 59 | 65 | 71 | 1105 | 562 | 366 | 427 | 466 | 467 |

Type 02 Dimension

| NPS | Ripple | Working Pressure(bar) | Effective | Max. | Supplied Length(mm) | ||||||||

| 10 | 16 | 25 | 10 | 16 | 25 | area | OD. | ||||||

| DN | qty | Axial Compensation(mm) | Force for Compress(N/mm) | (cm2) | (mm) | Flanged End | Welded End | ||||||

| 32 | 16 | 41 | 36 | 31 | 14 | 32 | 47 | 16 | 225 | 224 | 291 | 316 | 321 |

| 40 | 16 | 41 | 36 | 31 | 22 | 45 | 55 | 23 | 244 | 230 | 304 | 319 | 334 |

| 50 | 16 | 41 | 36 | 31 | 35 | 35 | 70 | 37 | 259 | 240 | 342 | 347 | 372 |

| 65 | 12 | 38 | 34 | 29 | 32 | 40 | 50 | 55 | 270 | 260 | 334 | 340 | 362 |

| 80 | 10 | 49 | 43 | 38 | 21 | 26 | 33 | 81 | 284 | 270 | 368 | 374 | 390 |

| 100 | 10 | 64 | 57 | 49 | 40 | 50 | 63 | 121 | 304 | 305 | 381 | 387 | 409 |

| 125 | 9 | 66 | 58 | 50 | 36 | 45 | 56 | 180 | 334 | 382 | 386 | 388 | 414 |

| 150 | 8 | 64 | 54 | 46 | 51 | 59 | 65 | 257 | 364 | 356 | 399 | 402 | 427 |

| 200 | 6 | 59 | 53 | 48 | 52 | 58 | 78 | 479 | 442 | 340 | 402 | 402 | 426 |

| 250 | 6 | 87 | 79 | 71 | 35 | 39 | 47 | 769 | 507 | 393 | 459 | 493 | 399 |

| 300 | 6 | 87 | 79 | 71 | 37 | 41 | 45 | 1105 | 562 | 464 | 525 | 564 | 565 |

What applications are metal expansion joints commonly used in?

Metal bellows and expansion joints are commonly used in a variety of applications to compensate for thermal expansion, vibration, misalignment, and other types of movement in pipelines and equipment. Here are some common applications for metal bellows and expansion joints:

•HVAC systems: Metal bellows and expansion joints are used in heating, ventilation, and air conditioning (HVAC) systems to absorb thermal expansion and contraction caused by changes in temperature and pressure.

•Aerospace industry

•Petrochemical industry

•Power generation

•Medical equipment

•Automotive industry

•Semiconductor industry: Metal bellows and expansion joints are used in the semiconductor industry to compensate for movement and vibration in vacuum chambers and other equipment.

How to select the right metal expansion joint for my specific application?

Selecting the right material for metal bellows and expansion joints is important to ensure they are durable and reliable in specific industry applications. Here are some factors to consider when selecting the material:

- Temperature: The material should be able to withstand the temperature range of the application. Different materials have different temperature limits, so it’s important to choose a material that can handle the expected temperature range.

- Corrosion resistance: In industries where corrosive substances are present, it’s important to choose a material that is resistant to corrosion. Materials such as stainless steel and Inconel are often used for their corrosion-resistant properties.

- Pressure: The material should be able to withstand the pressure of the application. Different materials have different pressure ratings, so it’s important to choose a material that can handle the expected pressure range.

- Flexibility: The material should be flexible enough to accommodate movement and vibration in the application. Materials such as Inconel and titanium are often used for their high flexibility.

- Cost: The cost of the material should be considered in relation to the specific industry application. Some materials are more expensive than others, so it’s important to choose a material that is cost-effective for the application.

It’s important to consult with a manufacturer or supplier of metal bellows and expansion joints to determine the best material for a specific industry application. They can provide guidance and recommendations based on their expertise and experience in the field.

Bellows Systems engineering and technical sales staff can assist you in making right material selection based on your application.

FEATURES

Absorb Axial movements (extension and compression).

Axial movement is the change in dimensional length of the bellows from its free length in a

direction parallel to its longitudinal axis.

Absorb Lateral movements.

Lateral movement is the relative displacement of one end of the bellows to the other end in a direction perpendicular to its longitudinal axis.

Absorb Angular and Torsional Movements.

Angular movement is the rotational displacement of the longitudinal axis of the bellows toward a point of rotation. Torsion refers to twisting one

end of the bellows with respect to the other end, about the bellows centerline.

Reduce Vibration.

Rubber expansion joints isolate or reduce vibration caused by equipment. The transmission

of vibration is reduced and they protect equipment from these adverse effects

Dampen Sound Transmission.

Rubber expansion joints tend to dampen transmission of sound because of the steel rubber interface of joints and mating flanges.

Manual and Install Notes of the Rubber Joint

Application:

Oil & gas, Desalination, Cooling systems, Pumps, Chemical plants, Heating, ventilating

and air conditioning, Shipbuilding, Off-shore applications, Water treatment plants

Sewage, Sanitary piping systems, Pulp and paper plants, Piping systems for chilled or hot water, Cooling systems power generation, Phosphate plants, Potable water, Food process